Variable Drag System (VDS)

The VDS is an air-braking system designed to deliver a high-powered rocket to precisely one mile AGL. The VDS does this by actuating three aluminum 'drag blades' into the airstream surrounding the rocket, actively changing the vehicle's drag profile on ascent. The system responds to sensor data taken in real-time and ensures that the vehicle has the correct balance of kinetic and gravitational potential energy at all points in the flight to reach one mile AGL exactly. In the NASA Student Launch competition flight, the VDS successfully delivered the launch vehicle to 5,303 ft.: only 23 ft. from its target. The VDS also contributed to the team's Vehicle Design Award. More detail on this system can be found below and in the team's technical documentation.

VDS assembly

Design Overview

The VDS actively changes the drag profile of the launch vehicle on ascent by actuating three aluminum drag blades into the airstream surrounding the vehicle. With the flat faces of these blades perpendicular to the airstream, the VDS is able to increase the projected area of the vehicle by a factor of 1.28 and the coefficient of drag by an estimated factor of 1.35.

Simulation

To predict the performance of the VDS and the launch vehicle, I developed a simulation in Mathworks' Simulink shown to the right. This simulation allows the team to predict mission performance for each launch with unique and customizable weather scenarios, 6DOF equations of motion, and a launch animation. Future improvements include a better aerodynamic model and hardware in the loop capabilities.

VDS rendering (top view)

Key Components

The three drag blades are driven by a single DC electric motor and can be actuated precisely to any position in its range with feedback provided by a rotary encoder. In this way, the drag blades can be actuated with the power of a DC motor but with the precision of a servo. A Teensy 3.6 microcontroller is responsible for controlling this actuation and for taking readings from a 9DOF sensor and a barometric pressure sensor. It uses this sensor data to determine the state of the vehicle on ascent and to respond with corrective braking accordingly.

Embedded Software

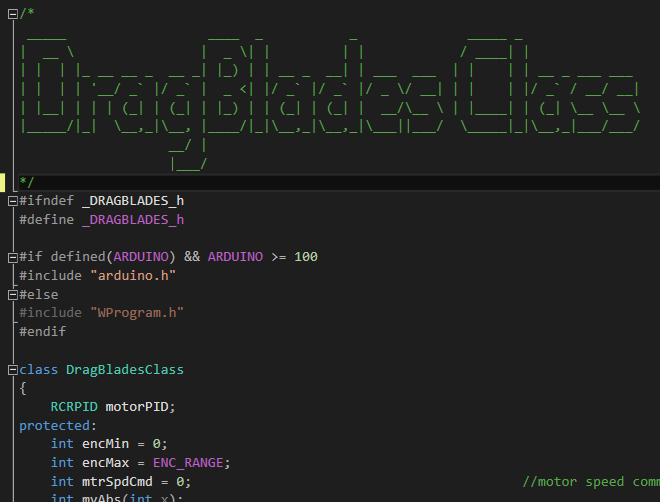

The embedded software for the VDS is written in a combination of C and C++, it is organized over five classes, and can currently operate at a speed of 90 Hz. This code is responsible for communicating with multiple sensors to determine the state of the vehicle, processing that data, and actuating the drag blades. The code does all of these things by integrating pressure, accelerometer, gyroscope, and magnetometer readings together with a Kalman filter. More detail on the VDS software can be found on my Github account.

A screenshot of the header file for the DragBlades class. This class is responsible for motor actuation, limit switch feedback, and rotary encoder feedback.

River City Rocketry team after receiving the Vehicle Design Award in the NASA Student Launch competition.

Mission success

The VDS has been demonstrated to successfully deliver the launch vehicle to one mile AGL +/- 33 ft. The thorough documentation of this system, the attention to detail in simulation, and its successful performance were all cited as contributing factors to the team receiving the Vehicle Design Award at the end of the 2016-2017 season.